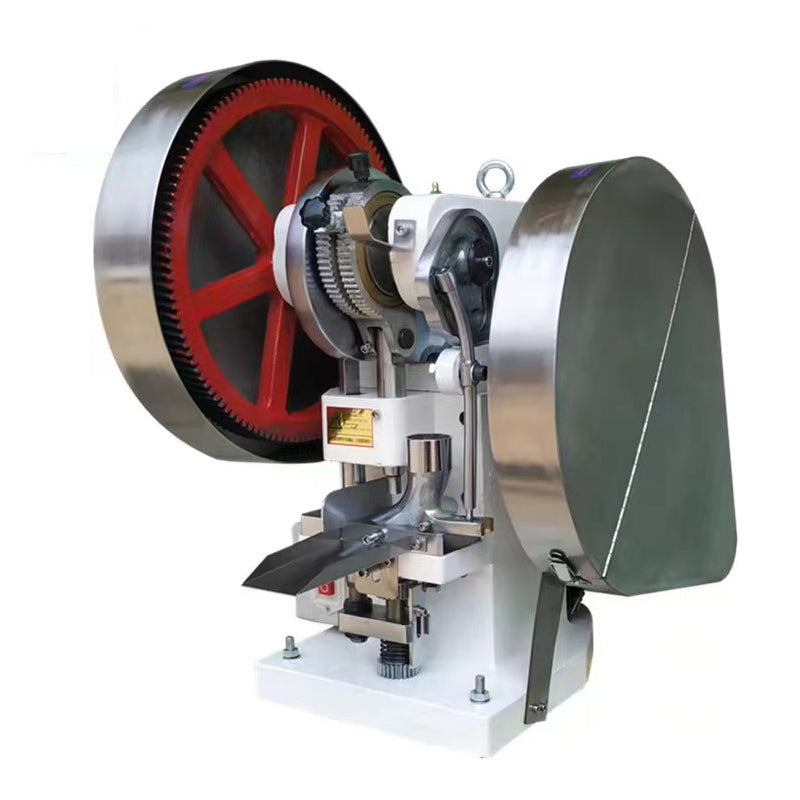

The tablet press mainly consists of transmission parts, turntable parts, pressure roller frame parts, crawler parts, lubrication parts and housings. Typical turntables have a 3-step structure with the upper perforator in the upper hole of the matrix, the middle perforator in the middle level and the lower perforator in the lower hole of the matrix. The forces generated by the transmission components cause the turntable to rotate, and the upper and lower dies move regularly up and down the defined path while the turntable rotates.

At the same time, the designer places the upper and lower pressure rollers in the respective positions in the upper and lower dies. As the upper and lower dies rotate and pass through the respective pressure rollers, they are pushed out of the pressure rollers so that the upper dies fall while the lower die moves up and compresses the material. The average weight of the turntable is fixed to the feeder and the material flows continuously through the feeder matrix into the center hole. The manual pressure adjustment wheel is used to adjust the height of the lower pressure wheel. The higher the position of the low pressure wheel, the higher the impact during compression.